Construction of Hyne Timber’s new Glue Laminated Timber (GLT) production plant is underway in Maryborough with Badge Construction. The building’s structure will be made up of the company’s own GLT, demonstrating their capability, backed by more than 40 years of GLT manufacturing experience. Cross Laminated Timber from Australian supplier, XLam will also make up some of the internal building and the internal stairs. Source: Timberbiz

Robert Mansell, Hyne Timber’s Business Development Manager, Commercial said construction of the new plant represents innovative, sustainable and quality construction.

“We know plantation pine is completely renewable but it is always refreshing to learn just how quickly a construction project’s volume of timber will grow back based on Australia’s plantation footprint,” he said.

“We know plantation pine is completely renewable but it is always refreshing to learn just how quickly a construction project’s volume of timber will grow back based on Australia’s plantation footprint,” he said.

“The volume of timber being used for this new construction project will grow back in under 8 minutes. Now that’s renewable.

“The structural strength to weight ratio achieved by using high grade Queensland grown softwood means the GLT beams, currently under manufacture, are 690mm deep and 210mm wide.

“To give some further context, the equipment this structure will house into the future will be capable of manufacturing GLT up to 1200mm deep and 240mm wide.

“We are also able to use our automated CNC machine for all the cutting and drilling making the manufacturing process significantly more efficient and 100% accurate for the connection detailing.

“We have been using our own GLT for our own commercial construction projects in Australia over many years and where GLT has been used in rafters, they bring light and space to work areas.”

All the GLT being used for the new plant is softwood Hyne Beam 17, locally grown by HQ Plantations and Responsible Wood certified in accordance with Australian Standards.

The timber is first milled and termite treated at Hyne Timber’s Tuan Mill near Maryborough before arriving at the GLT Plant for the final stage of manufacture and prefabrication ahead of installation.

The project’s architects from Hervey Bay, Bloc Design, have also benefitted from Hyne Timber’s recently introduced GLT Building Information Modelling (BIM) content. This BIM content was uniquely developed for Hyne Timber’s GLT as one of the deliverables for a proposal to the Queensland Government. Bloc Design’s Matt McKechnie said they were able to model the new structure using the Hyne Timber BIM content.

“Having BIM content specific to the manufacturer’s products makes our life easier especially when the content, such as Hyne Timber’s, is thoroughly set up,” he said.

“There is no guess work and we can be confident the beams are designed for manufacture.

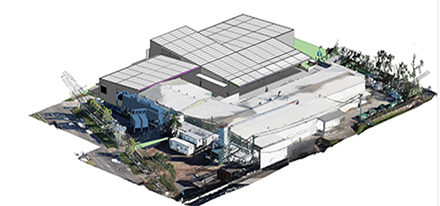

“We used a drone for the external site scanning and a laser scanner for the inside of the existing buildings to improve accuracy of the integration between the old and the new.

“This integrates into the BIM model seamlessly, making it completely accurate and de-risking the need for variations during construction.

“Further, the point cloud scanned data from the inside of the existing buildings calculates every bit of the interior space, even a corrugation in the roof to provide accurate cubic metre calculations.

“This provides accurate measures to comply with regulations such as fire compartment size compliance.”