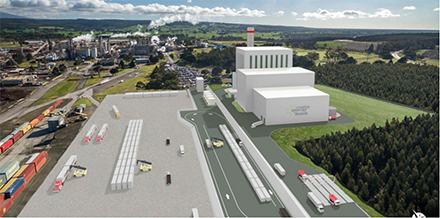

Australian Paper and its partner SUEZ are moving to the development phase of their $600 million energy-from-waste plant after a two-year detailed study backed the project at AP’s Latrobe Valley paper mill. The $7.5 million Energy from Waste feasibility study, co-funded by the Victorian and Australian governments, confirmed that the plant would be socially, economically, environmentally and commercially viable. Source: Philip Hopkins for Timberbiz

It would add a new dimension to the Latrobe Valley paper mill, the largest paper plant in Australia; stop waste being transported across Melbourne to landfill; save natural gas; lower carbon dioxide emissions; and create a massive economic boost, including hundreds of jobs in the Latrobe Valley and across the state.

AP’s chief operating officer, Peter Williams, said AP and SUEZ were now focussed on taking this important regional investment in the Latrobe Valley to the development stage.

“We will work to finalise approvals and seek to secure long-term waste supply contracts, as well as appoint suitable partners to undertake the engineering, procurement and construction phases,” he said.

The summary report found the plant would help solve the pending landfill closures facing south-east Melbourne.

“This could prevent about 550,000 tonnes of waste per annum being trucked across Melbourne from municipalities in the south-east to landfill sites located in the city’s west,” Mr Williams said.

“The EfW project is the missing link in waste management infrastructure for the south-east, creating efficient energy from residual household and commercial waste, achieving a more sustainable outcome than disposal to landfills. The facility would reduce CO2 emissions by more than 540,000 tonnes per year.”

With 80,000 tonnes expected also to be sourced from Gippsland, the total waste that would be processed at the Valley’s Maryvale mill is 650,000 tonnes.

The report also found that by replacing natural gas at the Maryvale site, AP would return enough gas to the market to meet the annual needs of up to 70,000 Victorian households annually.

“EfW technology is a proven and reliable low emissions technology, meeting the strictest European emission standards and has been used extensively in Europe, Japan and North America for decades,” Mr Williams said.

In the construction phase, the report concluded that the proposed plant would contribute $483 million to Victoria’s gross state product (GSP) and about $228 million to Victorian household income. “This represents an average of 1046 full-time jobs per annum in the Victorian economy over three years,” the report said.

The sectors most likely to benefit are construction, machinery and equipment manufacturing, professional, scientific and technical services, retail trade, chemical and non-metallic mineral product manufacturing, and finance and insurance services.

The construction impacts in the Latrobe Valley are a $203 million boost to gross regional product (GRP), just under $89 million in household income over the three years of construction. This represents an average of 454 full-time jobs over three years.

Once the plant is operational, the economic study estimates annual impacts of just under $199 million to Victoria’s GSP, about $76 million in household income and 911 full-time jobs when flow-on effects are taken into account.

When operational, the plant would annually contribute $96 million to the Latrobe Valley’s GRP, $20 million in household income and 265 full-time jobs when flow-on effects are considered.