Stuart Nash, New Zealand Minister for Economic and Regional Development, and Minister of Forestry, has opened the Wood Engineering Technology’s Optimised Engineered Lumber (OEL) production line in Gisborne. The plant is the only one of its type in the world and Wood Engineering Technology’s breakthrough product, OEL, is one of only seven engineered lumber products ever commercialised. Source: Timberbiz

“This is the biggest development in wood processing in over 30 years. But more importantly OEL is helping New Zealand address its biggest challenges – climate change, productivity, regional development, and the need for higher density housing,” Wood Engineering Technology Chair, Angus Fletcher said at the opening of the plant.

“For years New Zealand has been talking about moving up the value chain to improve our productivity in the primary industries. Our disruptive technology turns unprocessed logs, that would have otherwise been sent overseas, into an innovative high value product. And it does it in a fully automated, artificially intelligent, robotic factory in less than 12 hours while creating skilled, higher paid jobs in our regions. New Zealand innovation at its best.”

In April, Mr Nash announced a greater role for a public forestry service and signalled a more hands-on role for government working alongside the forestry sector. He identified a bright future for forestry and wood processing and noted it will be a key part of the country’s climate change response.

Mr Nash also pointed out that wood processing plants offer the opportunity to create high-tech, high-value products and by-products to diversify the income streams of foresters. For example, he suggested that innovative building products made from local wood will replace products such as concrete and steel. The OEL produced at the plant will be used solely for the domestic New Zealand market.

He has said that by retaining more wood processing onshore, we create local jobs and further support rural communities.

In Gisborne, Mr Nash also initiated the construction of Wood Engineering Technology’s second OEL production line. When complete the Gisborne location will have six production lines, producing up to 140,000 cubic meters of OEL, and employing more than 130 people.

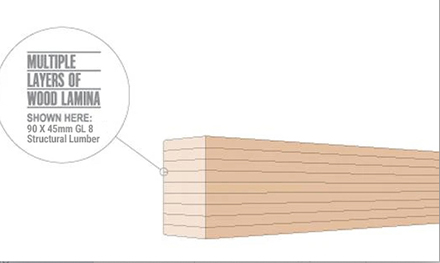

“OEL™ is 40% stronger than structural lumber,” Mr Fletcher said.

“This, and its guaranteed consistency, creates opportunities for wood-only, higher density, multi-storey residential buildings. OEL is an affordable zero carbon substitute for concrete and steel in building and construction. We are getting a lot of interest from those involved in providing social housing.

“The environmental credentials also stand out. Our research shows that one cubic metre of OEL has absorbed over 900kg of CO2 from the atmosphere, while the same volume of concrete releases over 400kg of CO2 into the atmosphere. OEL is produced in a Net Zero Energy plant and can play a leading role in helping to decarbonise our built environment.

“It also addresses the New Zealand productivity issue. OEL adds 300% to the value of an unprocessed log and has a productivity of greater than NZ$500 per worked hour. The New Zealand average is only NZ$68 per hour worked. Our little plant in Gisborne is certainly punching above its weight.

“After 16 years in development, we would not be here today without the support of our partners and funders. Specifically, I must thank the Government’s Provincial Growth Fund, Technology NZ, Callaghan Innovation, Scion and Trust Tairawhiti.”