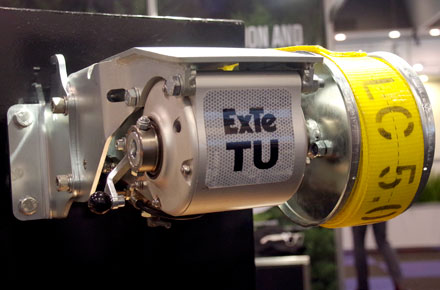

Forest Centre is the supplier of Swedish made ExTe load binding products such as the TU Tensioner and has been since 1992. The company has amassed a great deal of local load expertise during that time. Source: Timberbiz

Logging and timber haulage customers have been using the ExTe auto load binders that operate from the truck’s existing air system, making the task of load restraint simpler and safer with great success.

Air pressure does all the hard work, quickly tensioning cargo straps once activated, then actively applying post-tension to the load whilst it is in transit.

That translates to no more straining on load binder bars or ratchet handles and no more stopping to re-tension straps every few kilometres if the load shifts or settles.

The ExTe load binders use the the truck’s air system to activate and don’t rely on the physical strength of the operator. Once they are activated the units continue to monitor and adjust according to conditions.

All you have to do is place the load restraints in the right place and open the air valve to apply tension.

Tension force can be adjusted by using a small in-line adjustable air regulator with a gauge. A regulator can be used to adjust either a whole series of auto-tensioners, or if necessary each individual unit.

As a rough guide, the TU tensioner provides around 100kg of pre-tension per Bar of air pressure (when measured in a straight-line pull with 2.5 turns of webbing strap around the axle).

The standard axle types can accommodate a few different types of lashing, with either 50mm or 75mm webbing straps up to 9-10M in length and 6mm high grade chain.

Slip-through lashing can be used (similar method to a hand ratchet strap), where excess webbing is pulled through the axle before tensioning.

The system runs on its own main supply line, connected to the vehicle or trailer air tank via a pressure protection valve and master on/off service tap. The protection valve will shut off if there is a drop below 6 Bar (around 85PSI), isolating the tensioner supply and retaining air system integrity for the rest of the vehicle.

In the unlikely event of any air line damage, each tensioner can be operated or isolated individually.

Without air, an auto-tensioner can simply be used like a manual cargo winch, with a mechanical ratchet engage and release function.

Not only are these tensioners safer to use and reduce the risk of operator injury but they also make the job of loading a truck faster saving time, which in the end is money.

For more information visit www.forestcentre.com.au