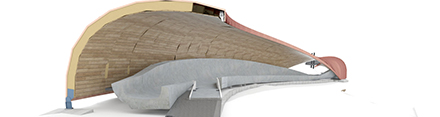

A 1350m long bobsleigh, luge and skeleton track at the Thuringian Winter Sports Centre in Oberhof will have a freestanding complex wooden roof of curved plywood free form shells glued directly on milled arches. Source: Timberbiz

The sports centre is currently undergoing extensive modernisation and renovation works. ZÜBLIN Timber was chosen to handle the factory planning, production and installation of a major part of the wooden roof for the artificially refrigerated sliding track. The contract value for ZÜBLIN Timber amounts to approx. € 4.6 million.

The challenging sliding track is roofed over 75 % of its length. The venue features a vertical drop of almost 100 m with an average gradient of 9.2 % and winds its way through 15 curves.

ZÜBLIN Timber is responsible for the complex roofing of the track from curve 6 to 7 and from curve 11 to 15.

The roof is largely free-standing with only a few supports. The structure complies with state-in-the-art standards while granting visitors and television crews the best possible line of sight.

The approximately 4500m² roof construction consists of nearly 300 glued, curved plywood shells with a surface area of up to 18 m². The shells are designed as free-form structures and are glued directly onto milled arches. On the inside, the new roof construction is fitted with a wooden strip formwork.

The team from ZÜBLIN Timber is also covering about 500 m² of the existing roof with a wooden ceiling on the inside using 153 individual 3.4 m² elements.

LENO cross laminated timber boards are being attached to the steel construction over an area of 739 m².

The track was inaugurated in 1971 and had its first complete overhaul in 2004. During the winter months, work will be suspended for several weeks due to training, competitions and preparations for the Olympic Games. The renovated track should be ready to host the Luge World Cup in January 2022. The World Luge Championships are scheduled to take place in Oberhof the year after that.