George Seymour, Jon Kleinschmidt, Cameron Dick, Bruce Saunders, Chris Hyne and Greg Moynihan

Hyne Timber was joined by the Acting Premier and Minister for State Development, Manufacturing, Infrastructure and Planning, the Honourable Cameron Dick, local member, Bruce Saunders MP and Mayor, George Seymour to officially turn the first sod ahead of construction of its new Glue Laminated Timber (GLT) production plant. Source: Timberbiz

News of the massive capability expansion in Maryborough was announced last October after the company secured a grant through the Queensland Government Jobs and Regional Growth Fund.

During the sod turning ceremony, Hyne Timber’s CEO, Jon Kleinschmidt said the new building will be constructed using the company’s own products.

“The new building will be constructed using our own GLT, manufactured at our existing plant in Maryborough to further showcase capability and over 40 years of GLT manufacturing experience,” Mr Kleinschmidt said.

“Further, Hyne Timber remains committed to using Queensland products and services throughout delivery of this construction project with a priority on Fraser Coast businesses where possible.

“Every part of this development will celebrate and showcase Queensland businesses and skills as so many businesses and people have supported us over our 137 years of operations.”

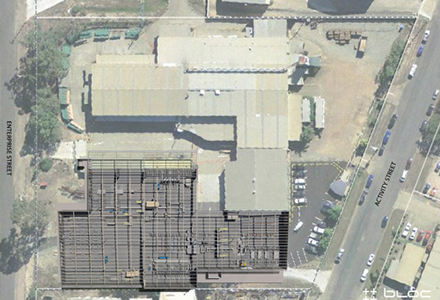

Site plan render, courtesy of Bloc Design

The Australian Forest Products Association (AFPA) Chief Executive Officer, Mr Ross Hampton said: “Not only is this a significant new $20 million timber industry investment, which will underpin 80 construction jobs and up to 42 new jobs in the long term, it is also a vote of confidence by both Hyne Timber and the Queensland Government in advanced manufacturing of innovative renewable timber products.”

“GLT is a flexible, zero waste and environmentally friendly alternative for steel and concrete in large-scale commercial and infrastructure construction projects,” he said.

“Hyne Timber’s investment will increase the supply of GLT in Australia providing developers with renewable timber product building solutions where traditionally they have not been considered an option.

“This new plant will make Hyne Timber one of the largest GLT manufacturers in the Southern Hemisphere.”

Hyne Timber continues to partner with Queensland company, Stirling Machinery, who are supplying the new production equipment which is made up of 14 different machines.

Queensland project management company, MCD is overseeing the site development working with Badge Construction and local Architect Adam Perrier of Bloc Design.

A number of other specialist consultants have been engaged all of whom are based in Queensland.

With construction to commence within a few weeks, up to 80 jobs will be created in what has been labelled by local service providers as one of Maryborough’s largest developments in recent history.

The recruitment of a range of permanent, specialist roles has already commenced with more operational and specialist jobs created as production scales up.

Hyne Timber’s GLT sales manager, John Hesse said the company has been experiencing an increase in both enquiries and demand in GLT as consumers search for sustainable building solutions.

Bruce Saunders, Cameron Dick and Jon Kleinschmidt with GLT Samples

“There is little doubt that responsibly sourced timber is experiencing a renaissance for a range of reasons but predominantly for its environmental credentials,” he said.

“This new, highly automated plant will increase volumes, improve the speed of delivery while broadening our product capability to capitalise on new growth opportunities,” Mr Hesse said.

Feedstock to meet the increase in capacity will be secured from Hyne Timber’s own sawmill, also located near Maryborough.