Komatsu Forest in Umeå, Sweden is implementing one of the largest investments in industrial Sweden. It will be a future-proof factory with a focus on sustainable production. The company’s investment strengthens the region’s position as a leader in the field of forest technology. Source: Timberbiz

Komatsu Forest is one of the world’s leading manufacturers of forest machines. The company sells its products all over the world and is wholly owned by the Japanese company Komatsu Ltd.

“The forest industry is an industry for the future. The next decade we see how new innovative and climate smart products will be produced from wood fibre. We want to invest in the future and see that the best conditions for us to do so are in Umeå,” Martin Ärlestig, factory manager Komatsu Forest said.

Komatsu Forest has headquarters and manufacturing in Umeå, where approximately 530 of the company’s employees are located. The new factory will be built on the industrial area Klockarbäcken in the outskirts of the city and the company has done a feasibility study to assess the entire project, including construction and transfer of operations while keeping the high productivity levels intact.

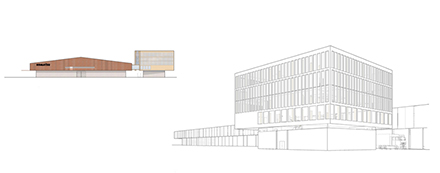

The start of construction is estimated to be in early 2019 and the plan is that the finished factory will be inaugurated in 2021 and will be something of a landmark.

“We will build a future-proof factory, where we can lay the foundation for the next generation of forest machines. In the new premises, we will be able to accommodate both production and development.

“We are investing in a factory that meets our needs here and now, but also gives us room to grow for the future,” Mr Ärlestig said.

The factory is one of the largest investments currently in industrial Sweden and will have a strong focus on sustainability and IoT. The factory will be carbon neutral in its production, which is achieved through efficient energy supply with solar panels, modern building techniques and geo energy.

The location at Klockarbäcken in Umeå is also an important factor, since the proximity to the railway means that an increased share of the company’s goods can be transported by rail.

As for IoT, Komatsu Forest will take a step towards the fourth-generation industry, where the company’s manufacturing process will be connected.

“This means many advantages, including that we can monitor quality, availability and safety in detail and that customers will experience higher flexibility and shorter lead time,” Mr Ärlestig said.

The ambition is also that the new factory will strengthen the region’s position as a leader in the field of forest technology.