A massive accident and cost overrun at a landmark CLT project in Oregon in the US has been cited as a warning to the burgeoning CLT industry in Australia. Source: Philip Hopkins for Timberbiz

Chris Lafferty, manager of research and development at Forest and Wood Products Australia, said the problems at a big $US79 million CLT project at Oregon State University – the glue failed, a heavy panel collapsed, with many panels being replaced – should be examined by the growing Australian CLT sector.

He was speaking at a recent FWPA seminar on Next Generation Timber Products at Melbourne University. The issue was highlighted in an article by The Oregonian newspaper.

The Oregonian reported that in March this year, a 455-kilogram CLT panel in the third floor of a new three-floor building, Peavy Hall, collapsed on to the floor below.

Engineers traced the panel’s failure to the glue. Further examination showed at least 85 panels had to be replaced.

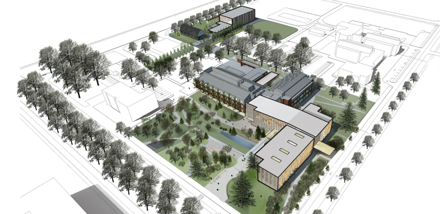

The project at the university was, ironically, a new building for the forestry school, designed to make a statement for CLT as the harbinger of a revitalised forest products market.

“Peavy Hall made a statement all right: about the risks of new technologies and getting caught up in the enthusiasm of the next big thing,” said the reporter, Jeff Manning.

The contract stipulated local content, so an inexperienced CLT builder, DR Johnson, won the contract ahead of an experienced Canadian company. Johnson’s president, Valerie Johnson, sits on the forestry school’s board of directors.

At the same time, the laminated timber movement was also hit when developers, citing construction costs, cancelled a 12-sorey building in Portland. It would have been the tallest wooden building in the US.

This came against the background of a bipartisan political push where the Oregon Building Codes Structure Board in August allowed wood-framed buildings as high as 18 stories, three times the previous effective limit.

A key motive was economic development, particularly in rural and regional Oregon, and wood’s positive climate change qualities.

US firefighters however, have been uneasy at high, wooden buildings but had no issue with the three-storey Oregon structure.

Prominent engineered wood advocate from Vancouver, Michael Green, who has been a guest in Australia, was chosen as the architect for Peavy Hall. He subsequently said he had never heard of a collapsing CLT panel before.

The efforts to determine the extent of the damage and resume construction were protracted, but DR Johnson admitted its liability.

An internal audit revealed that crews had been instructed “to warm the lumber in stacks under tarps”, which were then glued together to make the panels.

“Some temperature variations inadvertently caused premature curing of the adhesive, resulting in poor bonding,” the company said.

Oregon State University, however, maintained its confidence in DR Johnson and continued to rely on the company to make the replacement panels.

Four months after testing began, core samples had been taken from every one of the 700 panels. The various parties and experts reached a consensus on construction, and work on Peavy recently resumed. However, there was still disagreement on the number of panels that needed replacing.

The Oregonian reported that the new Peavy Hall is divided into Zones 1, 2 and 3. A total of 40 bad panels were found in Zone 1. In Zone 3, the panels were never installed and were being stored, but testing of the panels showed 45 of the 71 would need to be replaced.

Zone 2 is where the collapse occurred and is at the centre of the dispute over how many panels must be replaced.

The additional costs have not been calculated and the university has vowed not to pay anything extra. A legal fight looms.

Sceptics such as the firefighters maintain the Peavy Hall debacle shows the safety of engineered wood needs to be reconsidered.

CLT supporters argue that Peavy was a manufacturing blip and would not slow CLT’s momentum.

“It’s a localised issue,” said Vancouver’s Green. “There’s no loss of confidence in the industry we’re seeing.”

DR Johnson’s CLT business is going strong; the company has 30 new employees and is running two shifts a day to meet demand.

The university now hopes to have Peavy complete and ready for occupancy by September next year. “Has this been a black eye?” the newspaper quoted a university spokesman as saying. “I prefer to think of it as a learning moment that we hope will never happen again.”