Smart, future proof solutions were at the top of the agenda this year at the five-day Ligna 2019 expo. And it was made clear at this is world-leading trade fair for woodworking and wood processing plant, machinery and tools that technology users are now “getting smart” with regard to digitization and automation.Source: Timberbiz

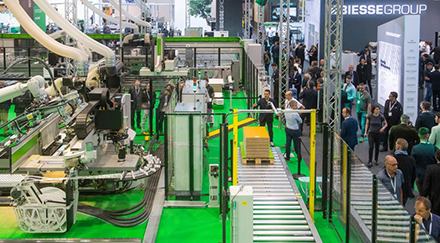

In 2019, major emphasis was placed on integrated solutions enabling companies of all sizes from niche woodworking firms to large-scale manufacturers to meet current market demands and prepare for future challenges.

Manufacturers of wood processing machinery for solid and engineered wood concentrated on automation and integrated systems, especially on modular technologies as a gateway to digitization.

Robotics technology is increasingly becoming the norm across all areas of industrial manufacturing, from materials handing to collaborative processing by humans and machines, right through to surface finishing.

The surface-finishing link in the value chain is becoming increasingly integrated into the overall production system. Automated guided vehicle systems are optimizing materials flows. Advanced central system control modules are intelligently managing the associated data and aggregating it quickly and efficiently for even the most demanding of single-batch production scenarios.

From the cloud technologies on show, it was clear that cloud-based data management has made the transition from proprietary systems to digital ecosystems. Thanks to a growing array of digital assistance solutions, the use of production data for preventive maintenance and production planning is getting more efficient all the time. At this rate, the vision – presented at this year’s LIGNA of end-to-end cloud-based material and tool management may soon be a reality.

Another vision that is getting closer and closer to becoming a reality relates to networking based on standardized communication protocols for all machines. On that score, the European Federation of Woodworking Machinery Manufacturers (EUMABOIS) and the German Engineering Federation (VDMA) used LIGNA to present a framework for a new P&W (Plug & Work) standard. The framework is a joint project by eight leading European manufacturers of woodworking machinery.

Another key trend in the woodworking and wood processing industry is augmented reality, most notably the use of VR headsets and tablets to visualize work-steps and machine states.

LIGNA 2019 also presented “all-in-one” solutions that can efficiently bring together multiple standalone machines to create integrated process flows.

The also featured new developments in saw technology that deliver industrial safety benefits. These involve high-performance sensor systems for material detection – a new generation of self-learning scanner technology that represents an exciting initial implementation of AI in woodworking.

The highlights of the wood-based construction area of the show included the world premiere of a six-axis aggregate that can process work-pieces on all sides without repositioning.

There was also a newly developed membrane press that can handle curved and uneven surfaces. And in the digital printing part of the LIGNA surface technology showcase, visitors saw new software that can generate extremely challenging decorative laminate layers, such as stone-look, in a single pass while maintaining an extremely high level of quality.

In the forestry technology section of this year’s show the spotlight was on climate change, Forestry 4.0, digital machine integration, supply chain tracking, timber flow management, the use of VR headsets for machine control, and apps for various in-forest operations.

Other key themes related to the development of forest access routes and new approaches to forest logistics.

The next LIGNA will run from 10 to 14 May 2021 in Hannover, Germany.