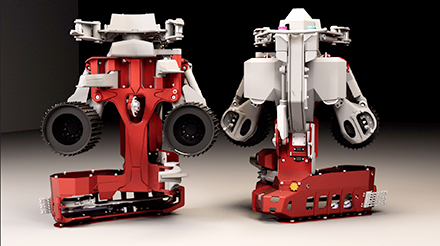

New Log Max 5000V is a versatile harvesting head suitable for a wide selection of carriers and for many types of felling. This is a head for those who want a balance between flexibility, capacity and durability. Source: Timberbiz

The new saw unit 318 MK2 will make your work easier. With careful material choices and new design ideas, the need for maintenance will be minimised, and durability will increase.=

The changes make it easy to change the bar, maintain the saw unit easily, and increase the durability to its maximum.

The 5000V measurement unit has got mechanical, electronic and hydraulic updates.

- The construction of the measuring wheel cylinder is updated.

- The hydraulic circuit is new.

- The measuring wheel arm and its attachment are reinforced.

- New contactless encoder in the measuring wheel.

- Two conical roller bearings that are lubricated from the outside.

Altogether, the changes will allow the measuring wheel to follow the contour of the stem even better and provide the best measurement result.

The contour of the saw box is changed, and the position of the saw unit has been optimized to handle trees with larger root bones and thus increase production significantly. The saw box also has a root bone plate to protect the chain and bar.

The saw box has also been extended and is now adapted for saw bars of 82 cm. The new 5000V easily handles large trees, both when felling and processing. The maximum cutting diameter is 74 cm.

The Log Max 5000V has new feed roller motors with hoses without banjo fittings. The new engines are of a high-flow model with increased efficiency, generating better performance for the harvesting head.

The changes provide a better and higher flow, which reduces heat development and thus reduces energy losses. It also increases the unit’s feed speed.

The feed wheel arms have also received an updated design to be able to process both coarse and thin logs better.

The hoses for the multi-stemming unit and the rotator control are on the left side of the felling link at 5000V. The updates make the hoses run inside the protective bar, less exposed and will make them last longer.

The attachment for the hoses for stump treatment and grease lubrication also has a new design, which means that the hoses are exposed to minimal wear and have increased durability.

To simplify service, facilitate transport and increase safety, a “Safety Pin” has replaced the safety chain, which forms a locking mechanism between the frame and the felling link. You can now link a bracket under the rotator to a stand in the frame with the help of a locking pin.

To increase durability and productivity, the frame construction of the 5000V has received several updates.

Here are some of the changes:

- The mechanical stops for the feed roller arms in the closed position are reinforced on the inside.

- The lower delimbing knife has received a mechanical stop integrated to the frame.

- The surface of the bottom plate has been reduced by approx. 15% to reduce snow packing.

- The main cover is reinforced to prevent it from being pushed in during snow packing.