Rehap’s latest developments in creating novel materials from agoforestry waste for use in the construction industry were presented at the 8th Nordic Wood Biorefinery Conference in October. The Nordic Wood Biorefinery Conference (NWBC) is a leading meeting forum for wood biorefinery professions and it took place in Helsinki, Finland. Source: Timberbiz

Karel De Winter, team leader in bioprocessing at Bio Base Europe Pilot Plant (BBEPP) and his colleagues presented the poster, “Creating novel materials from agricultural and forestry waste” as part of the Rehap project.

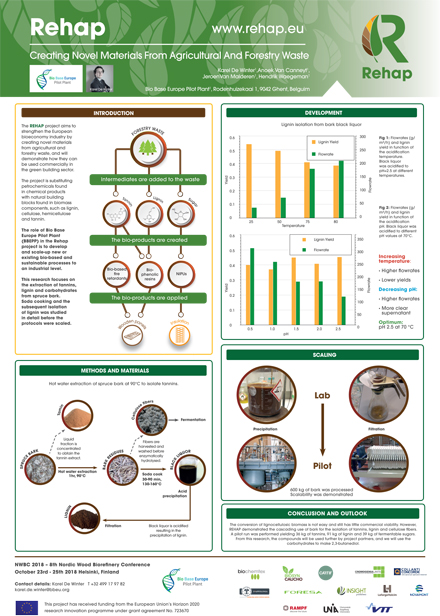

BBEPP, partner of Rehap, is tasked with developing and scaling-up new or existing bio-based and sustainable processes to an industrial level.

The research that was presented at NWBC focused on the extraction of tannins, lignin and carbohydrates from spruce bark. A detailed study on soda cooking and the subsequent isolation of lignin was completed before the processes were scaled.

The poster explained the soda cooking process and the precipitation of lignin. The soda cooking conditions were originated and developed by VTT, the latter was further developed by BBEPP and some optimisation on how to isolate the lignin took place.

BBEPP also developed these precipitation and filtration processes at lab scale before testing them at pilot scale, processing 600kg of bark and demonstrating their scalability. Results revealed the amount of lignin available.

The Rehap poster was among a turnout of 34 posters at the conference. The program also covered a range of topics in the form of keynotes and talks on forests, dealing with desire and greed in transforming environment; policies and global megatrends; industrial developments in biorefinery; new concepts and applications from wood based raw material; side streams into value-added products; processing and tailoring properties; and the application of these processes.

The conference provided detailed insight from paper and pulping industries, revealing a lot of work being done on the validation of lignin and the use of this material in other industries.

There was also a number of discussions on the alternative uses of bark for fuel processes by burning it and using it for energy.