Forest safety, improving productivity and getting workers off the felling site has been a major push for forestry managers, forest owners, logging contractors and equipment suppliers. Source: Timberbiz

To provide local operations with an insight into just where the technology is heading, internationally and locally, and the opportunities for using remote controlled and autonomous machinery, the SWC is running a meeting for the forest products industry in the lower South Island of New Zealand.

Modifying wood harvesting operations has been a key focus over the last few years. However, a move to increased mechanisation has been held back by skilled machine operator shortages that forestry companies are facing. With the ultimate goal being to have “no worker on the slope, or no hand on the chainsaw”.

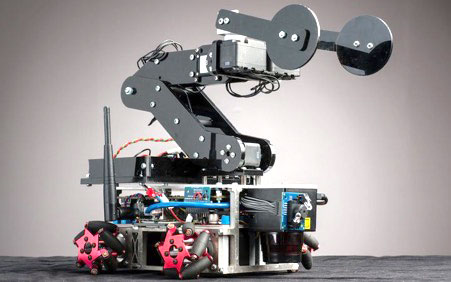

Technology development and the pace of change over the last couple of years has been rapid and exciting for the forestry industry. Recent research is suggesting that by 2019, 35% of leading organizations will be exploring the use of robots to automate operations.

The switch is underway.

Local forestry contractors in conjunction with local engineering companies in New Zealand have led the charge. Firstly, a myriad of new designs and operations, including vision systems for remote operation of equipment have been introduced to extract wood safely off steeper slopes.

More recently, tele-operation of wood extraction has successfully been trialed in New Zealand where the operator is sitting separately and away from the felling and log extraction operations. The operators sit in an operator’s cabin on or offsite with a live video and audio feedback from the machine transmitted to them.

In addition to improving worker safety, remote controlled felling will change how wood harvesting is undertaken on steeper terrain.

Having a similar impact on the wood supply chain are the rapid advances being made in loading and transporting wood. Like remote felling, virtual reality goggles have been introduced where operators can now operate log loading cranes remotely in the relative safety of the truck cab.

The objective, like remote felling is to develop the technology so that the operator is out of the truck and operating the crane remotely from a distance.

“Advancements in robotics and automation for forestry companies, everything from planting, silviculture, wood harvesting, extracting the wood from the forest site and transporting logs to the port or processing plant are moving at a fast pace” Grant Dodson, Chairperson of the Southern Wood Council (SWC) said.

Rien Visser, Forest Engineering, School of Forestry, University of Canterbury will be presenting his findings to local companies from just completed research undertaken for the Australian forest products sector in late 2017.

It looks at remote control, tele-operation and automation of forest operations, both inside and outside the forestry industry.

“There are some clear near-future opportunities, including operating extraction machines such as skidders and forwarders without an operator. This will not only increase efficiency, but allow good operators to work on more complex machines, and provide a unique opportunity for new equipment design” Prof Visser said.

“Advanced robotic systems are already commonplace in controlled workspaces such as factories. The future of wood harvesting systems is most certainly going to be robotic. The SWC meeting will be exploring the use of remote controlled or autonomous machines in these more complex environments like forestry operations,” Mr Dodson said.

The meeting will be held in Balclutha on Wednesday 14 March.