When we hear the word “disruption,” we tend to think of Apple’s iPhone destroying Kodak’s business model, Uber taking on the taxi industry or AirBnB reinventing the hotel game. But disruption is not just about technological change. Source: by Tony Arnel via Sourceable

In fact, as the twin drivers of climate change and economic imperatives encourage our industry to look for resource efficiencies, timber – one of our most ancient materials – is a new disruptive force that is poised to reshape the way we build.

No other material can help us meet the challenges of contemporary, sustainable construction nearly as well.

Timber has always been around as a building material, but this has been largely restricted to the residential sector.

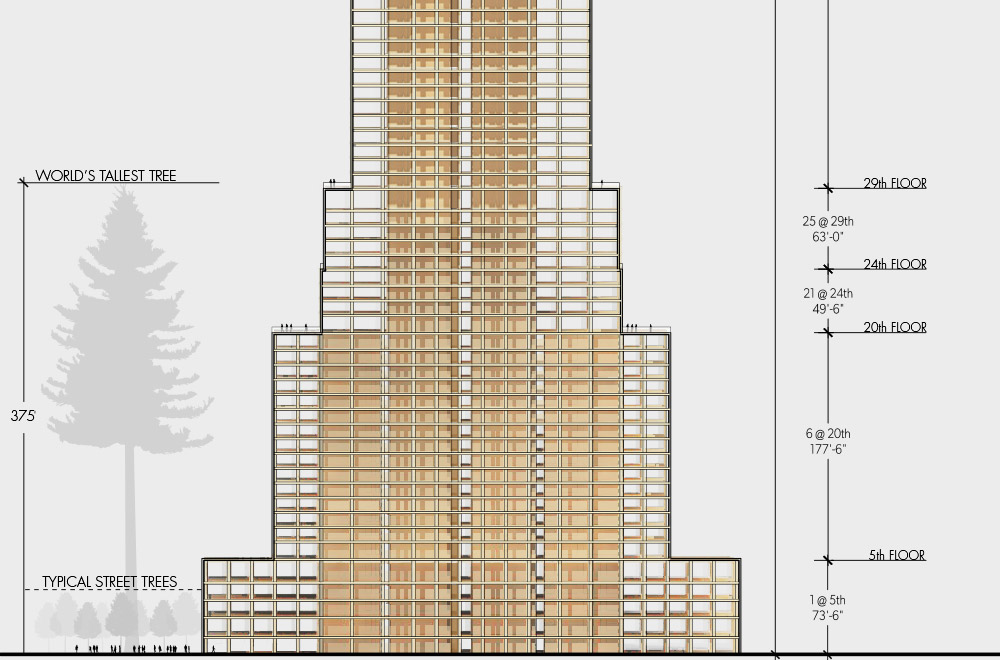

Largescale commercial development in timber is new. Lendlease has been an early adopter of timber high-rise construction.

When complete, the six-storey International House at Barangaroo South in Sydney will be the tallest timber office building in the world.

Made from cross-laminated timber (CLT) and Glulam (glue laminated timber), the building has been designed to meet Barangaroo South’s carbon neutral ambitions.

Lendlease’s managing director of Barangaroo South, Andrew Wilson, has said the “source of materials is important. To use at scale, timber is the only renewable resource.”

On May 1, 2016, the National Construction Code introduced a new ‘deemed-to-satisfy’ provision for timber buildings up to 25 metres, or eight storeys high, provided they include a raft of requirements, such as fire sprinklers and fire-resistant cladding.

This may spark innovative and entrepreneurial builders, many of them in smaller companies, to look at medium-rise timber apartments in our middle-ring suburbs – and at prices that the average Australian can afford.

Changes to the code will accelerate the use of prefabrication and modular construction – a method that delivers a range of benefits.

Timber can be grown, manufactured and cut to size close to site, making for quicker and more cost-effective construction.

Economic modelling undertaken by Forest and Wood Products Australia (FWPA) has found the shorter construction times required for wooden buildings can save up to 15 per cent on a project’s overall costs.

FWPA also estimates that the new code will provide a $103 million boost to the Australian economy over 10 years through environmental benefits, and reduced construction and compliance costs.

Timber is around 30% lighter than concrete or steel, potentially cutting crane, scaffolding and foundation costs.

Timber and engineered wood also offer advantages in terms of thermal and energy efficiency performance.

When combined with the precision delivered offsite on the factory floor, timber construction can enhance the quality of a build.

Research from Planet Ark has found that wooden interiors can also improve occupants’ emotional state, reducing blood pressure, heart rate and stress levels.

And of course, timber’s carbon storage potential is impressive.

Australia’s native forests, timber plantations and wood products are net absorbers of greenhouse gases, sequestering an estimated 56.6 million tonnes of carbon dioxide a year, and reducing our greenhouse gas emissions profile by almost 10%.

Our challenge is now to rethink conventional building. The current climate demands a move away from business as usual thinking. Timber may help us kickstart a whole new building movement.

FWPA has invested significant time into demonstrating that timber satisfies all safety standards while delivering environmental efficiencies.

This work is beginning to pay off, but the next step is to ensure we use locally-sourced materials and have the prefabrication plants to deliver product to market.

The Green Building Council of Australia’s proposed updates to Green Star, which will recognise and reward engineered timber in the Materials category, is a good start and will help incentivise the use of regionally-sourced and manufactured engineered timber.